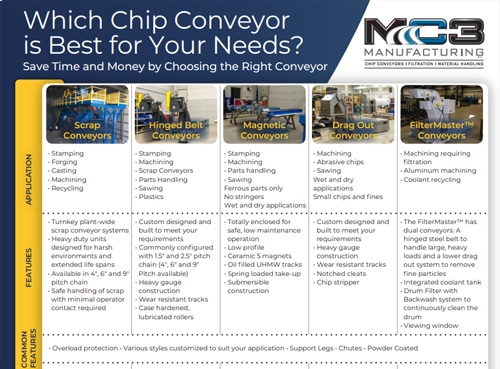

DRAG OUT CHAIN CONVEYORS

We specialize in innovative, versatile chip-handling conveyor solutions for our customers in industries as varied as machining, CNC machining, sawing environments, and similar industrial applications.

MC3 drag-out conveyors, sometimes referred to as drag chain conveyors, provide an economical solution for filtering and transporting fine chips. For wet chips or turnings, drag-out chain conveyor systems can provide efficient coolant filtration. It’s specifically designed for smaller chips and contaminants, but we also offer custom drag-out conveyors to handle large, saw-cut pieces, so you can rest assured that your machines are supplied with the purest coolant possible.

How Do Drag-Out Chain Conveyors Work?

Drag-out chain conveyors consist of a series of evenly-spaced paddles, also called flights or scrapers, connected to one or two continuous chains. These paddles drag along the bottom of a trough to collect and transport materials. The spacing between the paddles is intentionally designed to allow multiple inlets to feed materials onto the conveyor, as well as the ability to top-load materials. As the materials move down the conveyor, it deposits the contents in discharge areas, according to the system’s design.

MC3 can custom fabricate a drag-out chain conveyor to meet your specific requirements. We specialize in double-chained systems, but we can fabricate single-chained systems when required. Each system comes with the following standard drag-chain conveyor parts:

- Drag flights (with the option to include a stainless steel mesh drum to filter coolant)

- Filter box and clean coolant discharge area

- Chip discharge area

Drag-out chain conveyors require less power to convey materials, enhancing material-conveyance efficiency. Furthermore, they utilize up to 50% of the conveyor’s space to move materials, compared to the 20-45% standard with other styles. With versatile options for conveyor loading and discharge, they are an ideal method for transporting many wet or dry materials such as aggregate, pellets, scrap, and wood chips.

When adding a filter and coolant tank, a drag conveyor can effectively remove chips, swarf, and other unwanted materials from the coolant. As coolant and other liquids run through the filter, the drag scraper separates the contaminants and deposits them into the designated discharge area, while the filtered coolant is sent to its final destination. This simple process presents a streamlined solution to the problem of coolant filtration.

Features of MC3’s Drag Chain Conveyors

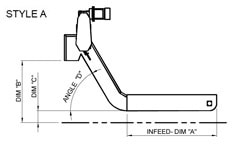

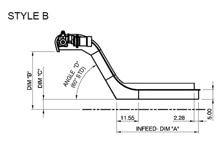

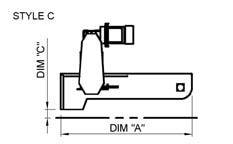

Rich in features with multiple functional and customization options, we fabricate powerful drag-out chain conveyor systems to meet your specific needs. Our facilities and modern equipment outperform our competition, allowing us to complete machining, forming, press brake, powder coating, and other advanced capabilities in-house for faster and more flexible production and delivery. Our drag conveyors are available in four styles and offer:

- Damage Resistance: The bottom of the chamber is resistant to scratches and other abrasions. This helps your machinery stay in good shape as it does its job.

- Easy Repairs: Replaceable cleats give you the ability to perform quick and easy repairs. Our machinery also includes casters, so you can move the equipment if necessary.

Drag-Out Conveyor Specifications

- Belt Speed: We collaborate with you to determine the optimal speed for your application

- Voltage: 110V (single phase), 220V (3 phase), 440V (3 phase), or 575V (3 phase)

- Available Controls: Start/Stop Variable Speed, Start/Stop/Reverse Variable Speed, Emergency Stop, and/or Zero Speed Proximity Sensors

Additional standard features of our drag-out chain conveyors include:

- Heavy Duty Gearmotor

- Friction Disk Torque Limiter

- High Carbon Steel Tracks / Wear resistant tracks

- Regreasable Bearings

- Robust construction

- Notched cleats

- Chip stripper

You can customize your conveyor solution with options including:

- Support Leg

- Side Mounted Gearmotor

- Epoxy Paint (you must provide your specifications)

- Perforated Bottom

- Stainless Steel body and/or chain

- Magnetic lower curve/bottom

- AR tracks and AR floor liner

- High-efficiency gear motors

- Standard ANSI or RS attachment chain

- Coolant pumps

- Coolant tank

- Controls

- Casters

Multiple filtration options are also available to fulfill the requirements of your application:

- Self-cleaning filter boxes: Box filters provide filtration to 250 microns and a self-cleaning function. This feature makes the MC3 drag-out conveyor a low-maintenance solution.

- Drum filters: Rotating filter drum w/ backwash

- Bag filters

Industries That Utilize Drag Chain Conveyors

At MC3, we design our drag-out chain conveyors for exclusive use in machining, CNC machining, sawing environments, and similar industrial applications. They are ideally suited to wet and dry handling of small chips and fines, including abrasive chips common to those environments. Configurable in both inclined and horizontal orientations, they may be installed in conjunction with other styles of open conveyors for extended capabilities in recycling and/or environmental protection.

Benefits of Drag-Out Chain Conveyor Systems

Drag-out chain conveyors offer a variety of advantages over other types of conveyor systems, particularly in machining applications, including:

- Drag flight conveyors reduce coolant waste by filtering out contaminants with minimal liquid loss.

- Drag-out conveyors are ideal for handling fines and small chips in dry and wet conditions.

- Efficient motors make the MC3 system a smart choice, especially when you need to increase production without increasing overhead costs.

- Intuitive controls make the equipment easy for staff to operate, which cuts down on lengthy training periods and unnecessary mistakes.

- Because chain speed is typically low, drag-out chain conveyors use less horsepower than other designs.

Choose MC3 For Drag Chain Conveyor Manufacturing

At MC3, our custom-fabricated drag-out chain conveyors and array of customization options provide solutions for wet and dry chip handling needs for machining and related industries. With our modern, in-house fabrication facilities, we offer shorter lead times and more flexibility than many other drag chain conveyor manufacturers, including capabilities for standalone custom fabrication services using your design and specifications.

Contact us today to discuss your needs with us, or request a quote for your next project.

Manuals & Tutorials

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Ready To Start Your Next Project?

Request a QuoteGet access now!

Please complete the form below to access the data sheets on this page. Click here to return home.

Drag Out Conveyors Quote Sheet Style A

Drag Out Conveyors Quote Sheet Style A Drag Out Conveyors Quote Sheet Style B

Drag Out Conveyors Quote Sheet Style B Drag Out Conveyors Quote Sheet Style C

Drag Out Conveyors Quote Sheet Style C