Indexing Conveyor

Indexing Conveyors

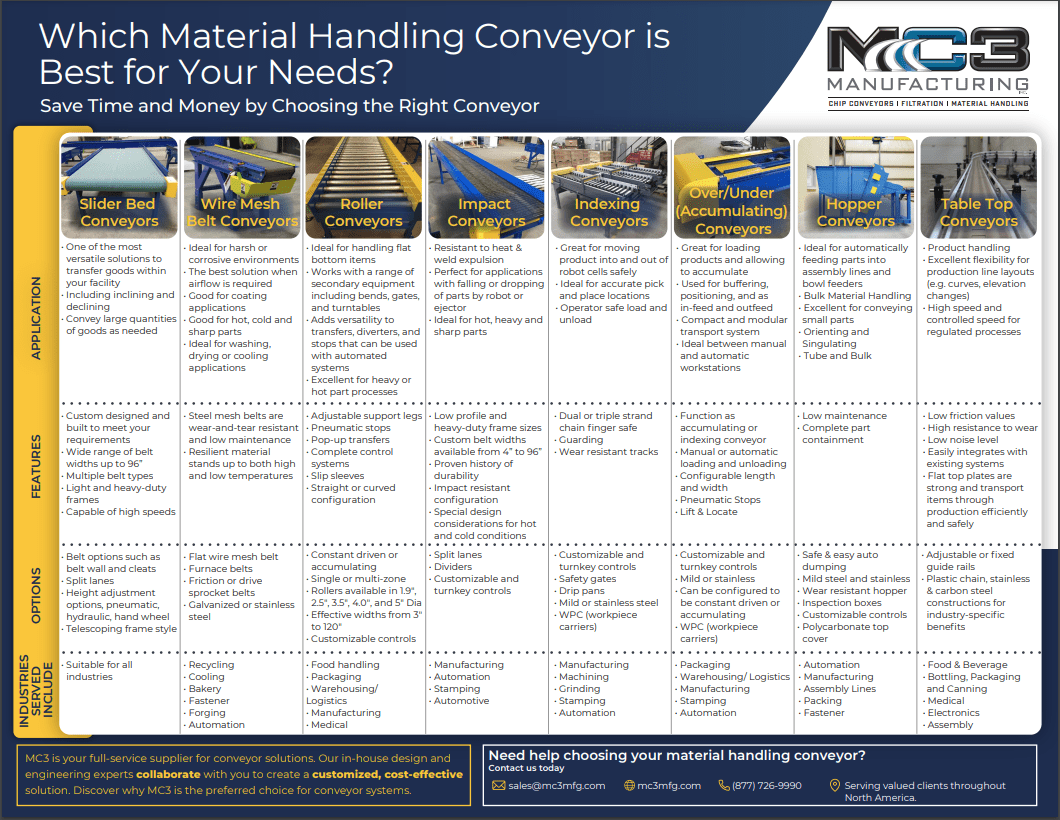

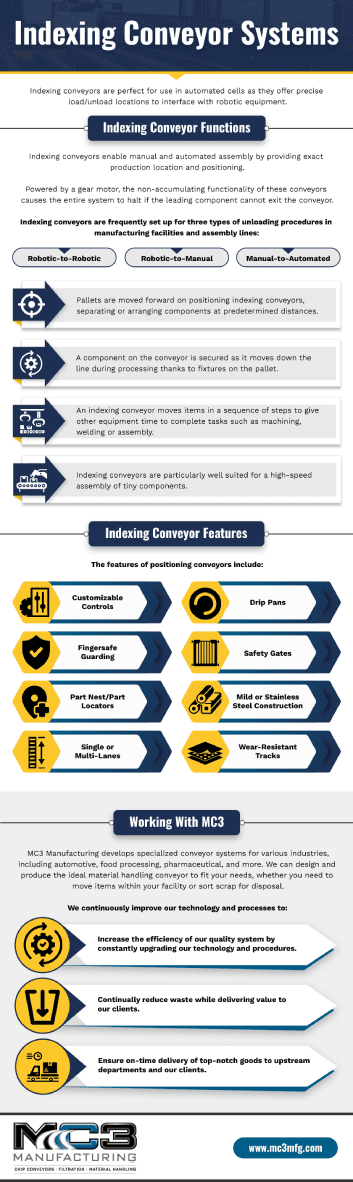

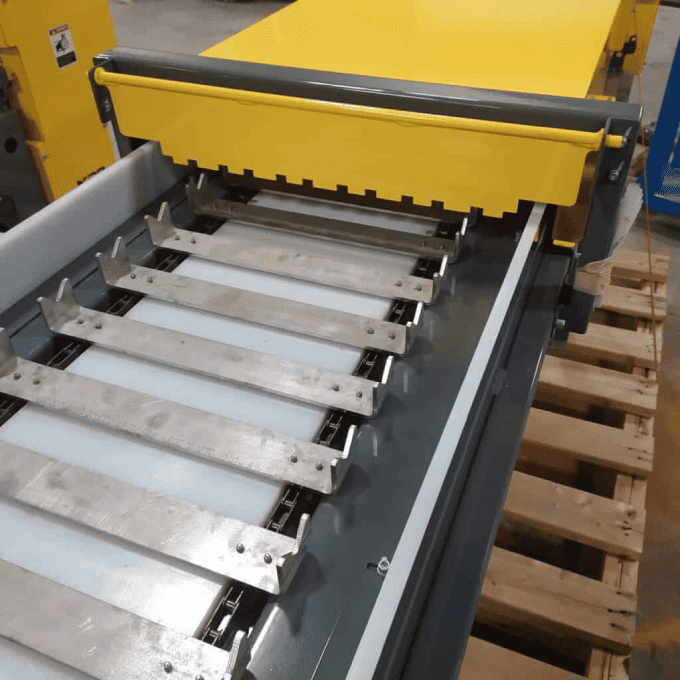

Indexing, pallet, or slat conveyors are non-accumulating conveyors with slats or pallets fixed to roller chains operated by a gear motor. They are frequently set up for manual loading and robotic unloading processes in assembly lines and machining centers. These conveyors are ideal for robotic unloading/unloading applications because the cycle time is known and controlled.

Indexing conveyors are perfect for use in automated cells as they offer precise load/unload locations to interface with robotic equipment. As experts in the field of conveyor construction, MC3 has the skill and expertise to provide precision indexing conveyors for your business.

Indexing Conveyor Functions

A production line’s overall functionality can be improved by using indexing conveyors, which have a range of applications. They enable manual and automated assembly by providing exact production location and positioning.

Powered by a gear motor, the non-accumulating functionality of these conveyors causes the entire system to halt if the leading component cannot exit the conveyor. Indexing conveyors are frequently set up for robotic-to-robotic, robotic-to-manual, and manual-to-automated unloading procedures in manufacturing facilities and assembly lines.

Pallets are moved forward on positioning indexing conveyors, separating or arranging components along the conveyor at predetermined distances. A product, assembly, or component on the conveyor is secured as it moves down the line during processing, thanks to fixtures on the pallet.

An indexing conveyor is made to move items in a sequence of steps instead of a continuous flow to give other equipment on the line time to complete tasks such as machining, welding or assembly. Often, sensors that monitor the flow and automatically control timing and operation are used to detect the indexing position of objects on belts. Indexing conveyors are particularly well suited for a high-speed assembly of tiny components.

Indexing Conveyors Features

Indexing conveyors have a wide range of features. Automation and machining applications, among others, allow workers to operate from either or both sides of the conveyor.

The features of positioning conveyors include:

- Customizable controls

- Drip pans

- Finger safeguarding

- Safety gates

- Part nest/part locators

- Mild or stainless steel construction

- Single or multi-lanes

- Wear-resistant tracks

Working With MC3

For machine enclosures, wash housings, material handling conveyors, and more, MC3 provides turnkey design and build solutions. MC3 Manufacturing develops specialized conveyor systems for various industries, including automotive, food processing, pharmaceutical, and more. We can design and produce the ideal material handling conveyor to fit your needs, whether you need to move items within your facility or sort scrap for disposal.

We continuously improve our technology and processes to:

- Increase the efficiency of our quality system by constantly upgrading our technology and procedures

- Continually reduce waste while delivering value to our clients

- Ensure on-time delivery of top-notch goods to upstream departments and our clients

Why Work With MC3?

At MC3 Manufacturing, we are dedicated to your project’s success, which is why we communicate with you at every step. Whether you sort solids or liquids, our custom conveyor filter systems accurately execute the job. MC3 is known for consistent on-time delivery. Due to our location on the Windsor-Michigan border, we have access to both Canadian and U.S. delivery points. Our products are specifically designed with you in mind. We develop and produce custom solutions tailored to your needs.

We can advise you on the conveyor belts and filter systems that will operate most effectively in your operation because we are leaders in our field. Let us know what materials you need to move within your facility, and we’ll work with you to devise a plan. Request a quote today and learn more about our services.

REQUEST A QUOTE

DOCUMENT CENTRE

- Documents not available.

Manuals & Tutorials

- Tutorials not available.

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.