Drum Conveyor Systems | FilterMaster Conveyor

FILTERMASTER™ DRUM CONVEYOR SYSTEMS

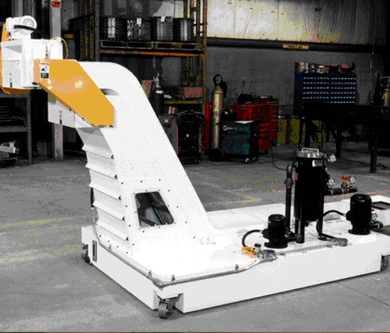

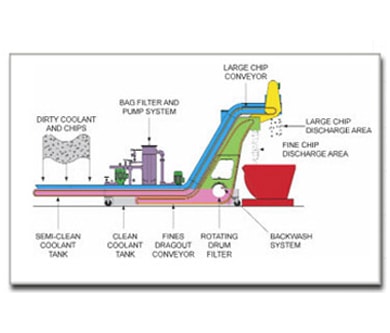

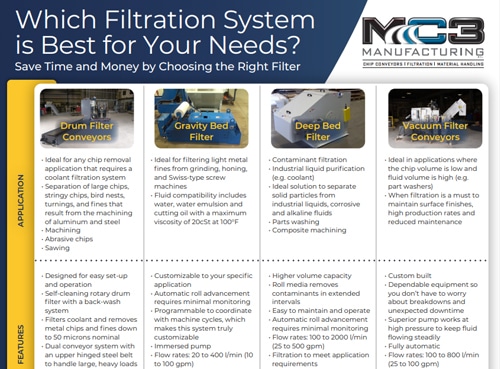

The MC3 drum conveyor systems are ideal for any chip removal application that requires a coolant filtration system. Dirty coolant can limit your machinery’s ability to operate properly, and it can wear down working parts more quickly. Our drum equipment is designed to filter coolant, remove metal chips and fines down to 50 microns nominal, and features a self-cleaning rotary drum filter with a back-wash system.

The MC3 Filter Conveyor has a dual conveyor system with an upper hinged steel belt to handle large, heavy loads and a lower drag out system to remove fine particles. The unit also features a small window, so you can keep an eye on the drum filter for quality inspection. Its proven design provides for low maintenance and durability and it is available in any size and configuration for special applications. Filter coolant and separate large chips, stringy threads, bird nests, turnings, and fines that result from the manufacturing of cast iron, aluminum, and steel.

FilterMaster Drum Conveyor Systems Benefits

Our drum conveyor systems are also easy to set up and operate. MC3 Manufacturing equipment works with a simple turn-key process, so you can have your machinery up and running in no time. We custom build equipment to ensure you get the exact configuration that will help your production excel.

Optional Drum Conveyor System Equipment:

- High pressure coolant system

- Coolant or spindle chiller

- “Plug It In & Go” turn-key system

- “Plug It In & Go” turn-key system

If you require coolant filtration, or you have other special needs that could benefit from a drum filter system, let MC3 Manufacturing provide the solution. Our expert team is trained to design and fabricate the right equipment to streamline your production line.

REQUEST A QUOTE

Manuals & Tutorials

- Tutorials not available.

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Ready To Start Your Next Project?

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.

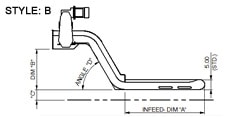

Drum Style Conveyors Conveyor Quote Sheet

Drum Style Conveyors Conveyor Quote Sheet