HINGED STEEL BELT CONVEYORS

Hinged steel belt conveyors offer distinct advantages over other types of conveyors. The durable system makes handling small items easier and can function at total capacity with minimal interruption.

MC3 Manufacturing offers high-quality hinged steel belt conveyors with various features and specifications to meet the demands of a broad range of applications and industries. The durable conveyor systems we provide offers many benefits and is an efficient addition to any manufacturing facility.

What is a Hinged Steel Belt Conveyor?

Hinged steel belt conveyors are durable systems ideal for handling small metal scrap and chips. Unlike traditional conveyors, their interlocking steel slats eliminate gaps, preventing small materials from falling through. This makes them suitable for various applications, including machining, die casting, stamping, forging, and scrap yards.

MC3 Manufacturing offers customizable hinged steel belt conveyors in various sizes and configurations to meet specific needs. They are known for their durability, minimal maintenance, and ability to handle a wide range of materials, including dry and wet scrap, hot and oily components, and even mixed chip loads.

Within a traditional metal belt conveyor system, there are gaps between the belt segments where small chips can drop through. This defeats the machine’s purpose. By using steel hinges, these gaps are eliminated, which makes it a more reliable conveyor belt for small scrap and fine chips. Our conveyor systems are durable, so you can depend on our equipment to keep your operation running smoothly with minimal breakdowns.

Our hinged steel belt conveyors are designed to last and require minimal maintenance, ensuring long-term operations in material handling and metal cutting applications. Hinged steel belt conveyors efficiently carry steel scraps, parts, and chips from steel presses and CNC machining centers. Our hinged steel belt conveyors are capable of transporting parts from one station to another, efficiently moving hot and oily components from punch presses, forging machines, and other sources to drums or hoppers.

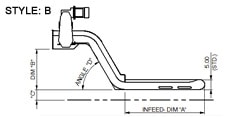

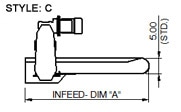

We engineer our conveyors according to customer specifications to provide an ideal solution for most machine tool applications. Featuring a low-profile design, these rugged conveyors can effectively manage small parts, scraps, stampings, turnings, and chips, whether wet or dry. We provide optional design modifications to meet the needs of specific applications which include elevating or horizontal configurations and multiple or single-unit systems.

We recognize that no two applications are the same, which is why we provide an array of options when it comes to the elevation angles, length, and width of our equipment to ensure that you get the perfect fit for your operation. With a high degree of design flexibility, we can fabricate conveyors with coolant reservoirs and tanks that match your exact specifications to optimize your machine tool applications that use cutting oil and coolant. Our conveyors can also be tailored to meet a variety of coolant filtration requirements and are suitable for a wide range of coolant flow rates (in GPM), providing the flexibility and adaptability your operation demands.

Features and Specifications of MC3’s Hinged Steel Belt Conveyors

We offer options with both a 1.5″ and 2.5″ pitch. Larger 4″, 6″, and 9″ pitches are also available for heavy scrap moving needs. We use only the highest-quality steel and expert fabrication techniques. Our team can customize your conveyor belt to the right width and pitch you need for your specific product. The hinged steel belt conveyor systems at MC3 Manufacturing provide simple maintenance and have dependable safeguards in place to prevent overloading and over-accumulation. Other features and options include:

- Plain, perforated, or dimpled-style hinged steel belt

- Conveyor Support leg

- Motor cover

- Cover with chip suppressor

- Diverters

- Configurable infeed and inclined guides

- Scrap trays/drawers

- Clean-out access

- Draining provisions

- Casters

- Coolant reservoir

- Filtration System

- In-line gear motor

- Paint to customer specification

CHIPMASTER™ Hinged Steel Belt Conveyors Standard Specifications

For our CHIPMASTER™ conveyors, we use reliable, standard components that are easily accessible to minimize production downtime and ensure quick replacements or repairs. Wiper cleats help to remove unwanted material on the return side, and a friction torque limiter prevents overload. The conveyor offers a superior appearance with a maintenance-free design and rounded corners to prevent chip accumulation. The machinery comprises an 11-gauge steel formed frame, high carbon steel tracks, an adjustable motor bracket, high-efficiency gear motors, adjustable take-up mechanism, and sealed bearings.

CHIPMASTER™ Hinged Steel Belt Conveyors Belt Specifications

Our CHIPMASTER™ steel belts are manufactured in-house with plain, dimpled, or perforated/dimpled surfaces. Made from 1045 CRS steel, the axles provide optimum wear resistance. Components include 11-gauge pans and interlocking 10-gauge steel side wings. The oil-impregnated and case-hardened rollers have tapered sides. We utilize standard parts to ensure swift delivery.

What Are Applications of Hinged Belt Conveyors?

Hinged steel belt conveyors are versatile conveyors used in various industries to handle a wide range of materials, including:

- Machining: Filtering chips and swarf from metal parts.

- Die casting: Removing scrap metal accumulated during the casting process.

- Stamping: Conveying metal stampings and preventing small pieces from falling through gaps.

- Forging: Transporting hot and formed metal pieces.

- Scrap yards: Sorting and managing various scrap metal.

- Other applications: Conveying finished parts, heavy items, and even mixed chip loads.

These conveyors excel at handling small items due to their interlocking steel slats that eliminate gaps, unlike traditional conveyors. They are also known for their durability, minimal maintenance, and ability to handle dry, wet, and even hot materials.

Typical applications for our hinged belt conveyors include filtering chips from the machining of metal parts and sorting scrap that accumulates from metal forming.

More versatile than other conveyor types, our heavy-duty hinged steel belt conveyors can process any volume of dry or wet material and are available in different paths to accommodate the needs of varying applications. The machinery can work with various metals, including aluminum, steel, and brass, and optimally handles mixed chip loads. Material handling capabilities range from die scrap and bushy materials to stringy turnings and broken chips.

What Are The Benefits of Hinged Belt Conveyors?

Hinged steel belt conveyors offer a multitude of benefits compared to traditional conveyors, making them ideal for diverse applications. Their interlocking steel slats prevent small items from falling through, ensuring efficient handling of scrap and chips. These versatile conveyors excel at handling a wide range of dry, wet, hot, and even mixed materials while maintaining durability and requiring minimal maintenance. They can be customized in size, configuration, and features to perfectly suit specific needs, and damaged sections are easily replaced without disassembling the entire system. Additionally, dependable safeguards prevent overloading and ensure safe operation, making them valuable tools in industries like machining, die casting, stamping, forging, and scrap handling.

MC3 Manufacturing’s hinged steel belt conveyor systems are designed to provide reliable transportation of small scrap and fine chips, eliminating gaps between belt segments found in traditional metal belt conveyors. Our systems have dependable safeguards to prevent overloading and overaccumulation, ensuring minimal breakdowns and optimal operation.

These conveyors are easily customizable and simple to maintain, meeting the demands of various applications, including heavy, large, hot, and oddly shaped items. Additionally, changing damaged belt sections is quick and easy, and the conveyor does not require disassembly. Our hinged steel belt conveyors are durable and reliable, thanks to high-quality steel construction, thoughtful design, and expert fabrication techniques.

Contact MC3 Manufacturing For Your Hinged Steel Belt Conveyor Systems

MC3 Manufacturing is a leading industry provider of hinged steel belt conveyors. We have the expertise and knowledge to provide quality products and services for varied industries and applications.

Our customers have trusted us for over two decades to provide high-quality conveyor systems that meet their application requirements. Browse our testimonials to see how our conveyor solutions have benefitted our long-standing clients. Contact us or request a quote to learn more about our capabilities and how we can supply your company with hinged steel belt conveyors that offer versatility and the ability to handle a broad range of products to meet your needs.

Manuals & Tutorials

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Ready To Start Your Next Project?

Request a QuoteGet access now!

Please complete the form below to access the data sheets on this page. Click here to return home.

Hinged Steel Belt Conveyors Quote Sheet

Hinged Steel Belt Conveyors Quote Sheet Hinged Steel Belt Conveyors Quote Sheet

Hinged Steel Belt Conveyors Quote Sheet