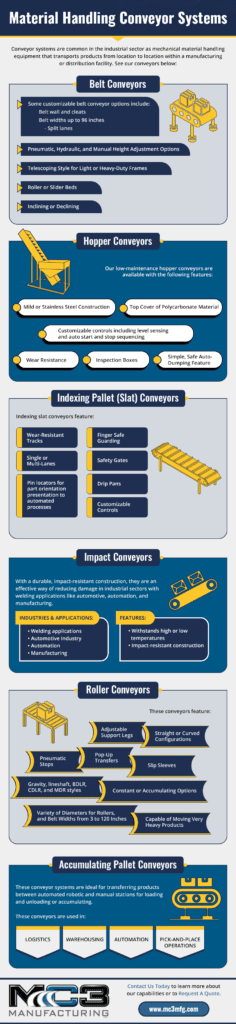

Material Handling Conveyor Systems

Conveyor systems are common in the industrial sector as mechanical material handling equipment that transports products from location to location within a manufacturing or distribution facility. Material handling conveyor systems provide efficient product handling and operational support for personnel and processes. There are many types of these conveyors available, such as accumulating pallet conveyors, indexing pallet conveyors, impact conveyors, among others, that are each best suited to specific applications.

At MC3 Manufacturing Inc., we create custom material handling conveyor systems based on a client’s specifications. This allows us to provide quality products with competitive rates and timely delivery. Through our collaborative design and engineering services, our team will develop a system that meets your needs, from belt conveyors to tabletop conveyors and more.

Belt Conveyors

MC3 custom-builds these versatile material handling conveyors for both bulk material and individual unit processing to suit all industries. Specifically, they have applications in distributing goods inside and outside of a facility, as well as feeding or removing individual units or components. Some customizable belt conveyor options include:

- Belt wall and cleats

- Belt widths up to 96 inches

- Split lanes

- Pneumatic, hydraulic, and hand wheel height options

- Telescoping style for light or heavy-duty frames

- Roller or slider beds

- Inclining or declining

Hopper Conveyors

Hopper conveyors from MC3 use varied belt types depending on the application, with common uses in manufacturing, automation, packing, and more. These hopper conveyors are capable of automated bulk material handling, singulating, orienting, and conveying small parts. Hoppers are ideal for feeding components into bowl feeders or assembly lines. Our low-maintenance hopper conveyors are available with the following features:

- Mild or stainless steel construction

- Top cover of polycarbonate material

- Customizable controls including level sensing and auto start and stop sequencing.

- Wear resistance

- Inspection boxes

- Simple, safe auto-dumping feature

Indexing Pallet (Slat) Conveyors

Commonly configured for manual loading and robotic unloading processes in assembly lines, indexing pallet or slat conveyors are non-accumulating conveyors that have slats, or pallets, fixed to roller chains driven by a gear motor. Indexing conveyors index components, arranging or separating parts by a predetermined distance on the conveyor. Fixtures on the pallets can keep a product, assembly, or component in place on the conveyor as it passes down an assembly line during processing. This equipment enables employees to work from either or both sides of the conveyor in automotion and machining applications, among others. Indexing slat conveyors feature:

- Mild or stainless steel construction

- Wear-resistant tracks

- Single or multi-lanes

- Pin locators for part orientation presentation to automated processes.

- Finger Safe Guarding

- Safety gates

- Drip pans

- Customizable controls

Impact Conveyors

Impact conveyors play a critical role in welding applications or operations with robots or ejectors dropping parts onto a conveyor belt within a weld cell and conveying to a location outside the weld cell for processing. With a durable, impact-resistant construction, they are an effective way of reducing damage in industrial sectors like automotive, automation, and manufacturing. MC3 can custom-make them to withstand high or low temperatures or with turnkey controls, and they come in:

- Low-profile and heavy-duty frame sizes

- Custom belt widths from 4 to 96 inches

- Split lanes

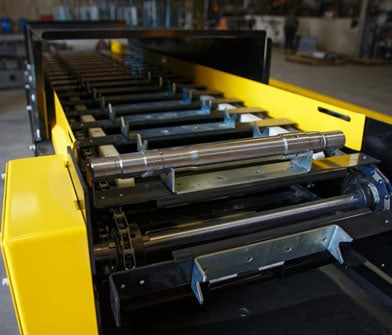

Roller Conveyors

Automated systems utilize roller conveyors to move, divert, and halt products in production. They accomplish this by integrating with secondary components like gates, bends, or turntables. Roller conveyors are specifically useful for processing components with flat bottom surfaces, heavy weights, or hot temperatures in industries including food handling, warehousing, raw metal processing, and logistics. These conveyors feature:

- Adjustable support legs

- Straight or curved configurations

- Pneumatic stops

- Pop-up transfers

- Slip sleeves

- Gravity, lineshaft, BDLR, CDLR, and MDR styles

- Constant or accumulating options

- Variety of diameters for rollers, and belt widths from 3 to 120 inches

- Capable of moving very heavy products

Accumulating Pallet Conveyors

Accumulating pallet conveyors, also known as over/under conveyors, are optimal for material handling. Using pallets fixed on a chain, this equipment incorporates the functionality of chain conveyors, pallet conveyors, and pallet return systems. The chain directs a pallet around a drive sprocket and then carries the pallet upside down, ultimately bringing empty pallets back to their starting positions. Featuring stops, these conveyor systems are ideal for transferring products, both inbound and outbound, between automated robotic and manual stations for loading and unloading, or allowing goods to accumulate on the conveyor. Their buffering capability results in reduced operator time and expenses in industrial sectors like logistics, warehousing, and automation. These conveyors also position products precisely for pick-and-place operations. Some over/under conveyor options include:

- Customizable pallet stops and fixtures

- Configurable dimensions

- Constant, indexing, or accumulating options

- Turn-key Controls

Conveyor Systems From MC3 Manufacturing

Regardless of your industry, material handling conveyor belts can play an integral role in transporting products from one point to another. Founded in 2000, MC3 specializes in the design and production of various high-quality custom conveyor systems and scrap conveyor systems. Our company is committed to delivering innovative machinery to provide optimal value for our customers. Contact us today to learn more about our capabilities or to request a quote.