Accumulating Pallet Conveyor

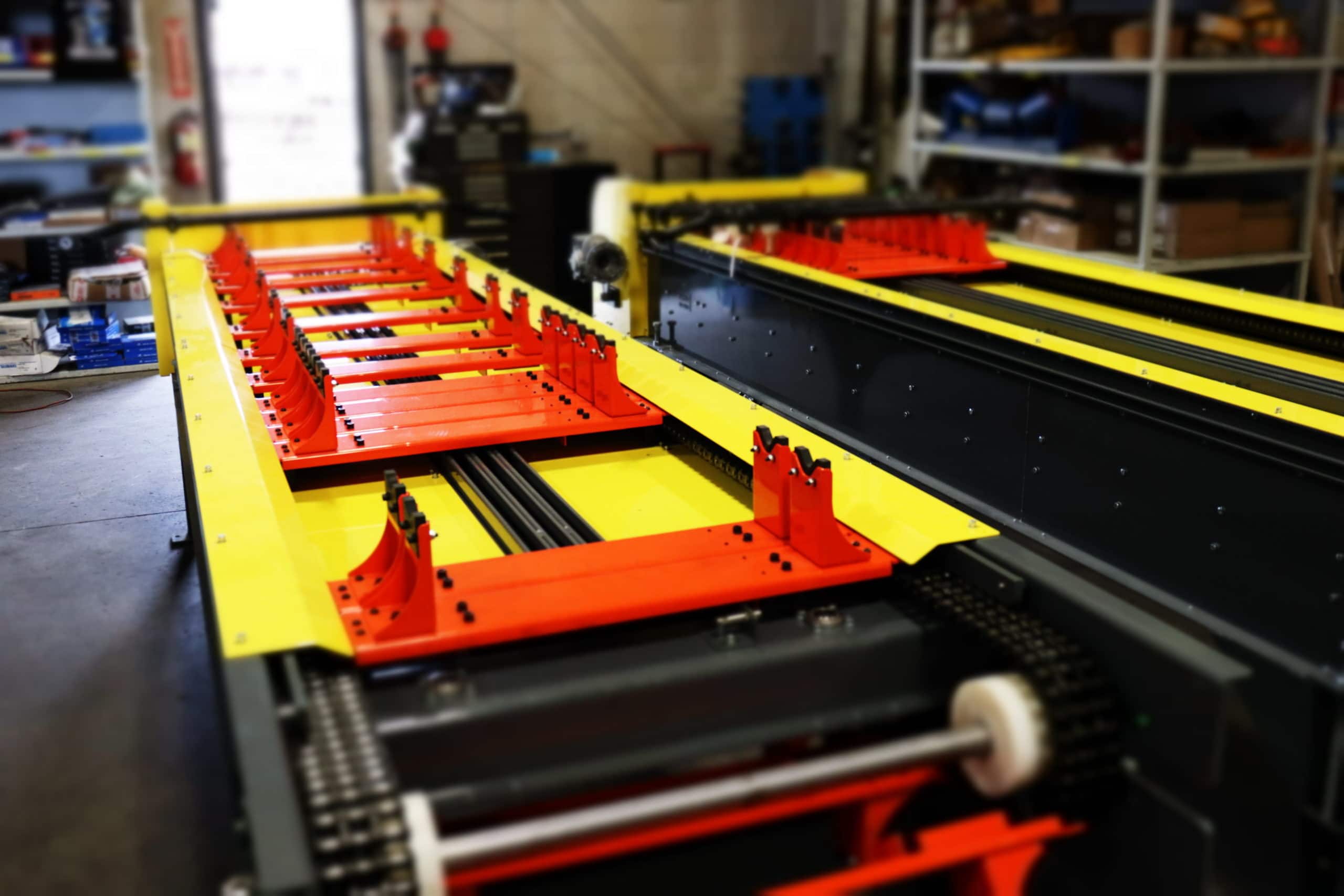

Also called over/under conveyors, accumulating pallet conveyors are an ideal solution for managing the flow of products in and out of work cells. They can transfer pallets of goods from one station to another and return the pallet after unloading, creating a closed circuit. Accumulating pallet conveyors reduce the operator’s workload by allowing the pallets of conveyed parts to collect at the end of a line and wait to be further processed. This allows an operator to service multiple cells or conveyors as the units do not need to be unloaded immediately.

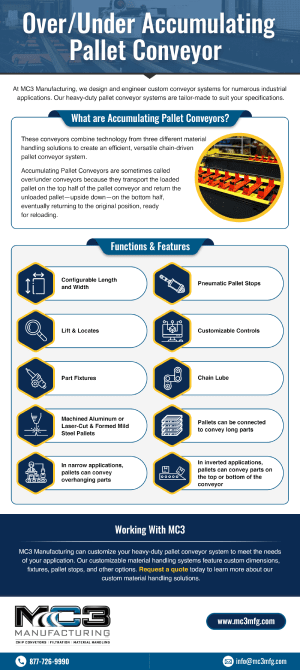

At MC3 Manufacturing, we design and engineer custom conveyor systems for numerous industrial applications. Our heavy-duty pallet conveyor systems are tailor-made to suit your specifications.

What Are Accumulating Pallet Conveyors?

Accumulating pallet conveyors are an excellent piece of equipment for material handling. They are sometimes called over/under conveyors because they transport the loaded pallet on the top half of the pallet conveyor and return the unloaded pallet—upside down—on the bottom half, eventually returning to the original position. The ability to return the pallet eliminates the need for an additional pallet return conveyor and creates a more streamlined, closed-loop system. These conveyors can be configured to be constantly driven or accumulating depending on the needs of the facility.

Accumulation conveyors leverage a chain system to pull pallets in one direction and allow the pallets to wait at the end of the system until the parts are unloaded. Within facilities, these conveyors are often used for buffering, positioning, and as in-feed and outfeed applications, and are ideal for interfacing between manual and automatic workstations.