Hopper Conveyor

Hopper Conveyor

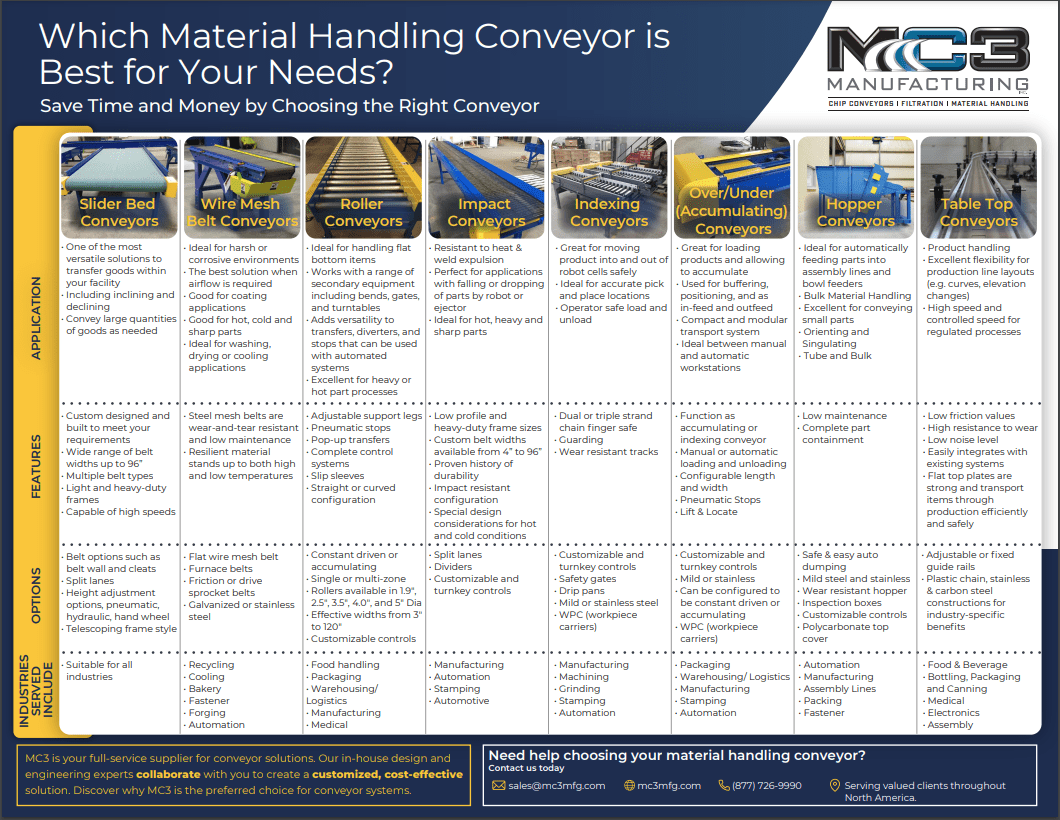

Just-in-Time production relies on components being on the line. Whether you’re assembling, processing, or packaging, the right parts have to be in the right place at the right time. That’s where having the right hopper conveyor system pays for itself.

Parts and components have to be where people need them. You can’t afford to waste time untangling, sorting, or straightening parts. Instead of employees fishing in several bins to get the parts they need, think how much faster your operation would be with hopper conveyors delivering individual parts. Hopper conveyors don’t just make the line faster; they make operations smoother, reduce errors, simplify training, and save space. That’s how an efficient line works.

We build hopper conveyors to meet your exact needs and increase efficiency. If your line operators have to dig in bins for components, they are costing you money and slowing everyone down. They’re also stressing their hands and wrists, increasing your support costs. If those parts have any sharp edges or points, the situation gets more critical in a hurry. So much better to have those parts arrive on a belt, spaced and oriented, just as the line needs them. Your employees are safer, healthier, and happier. The line is smoother and quicker. Downtime is, well, down.

That’s what hopper conveyors are all about. The hopper stores parts in bulk. The conveyor takes the parts at set rates and delivers them where they’re needed. That might be providing parts directly to the line, or it may mean feeding them into sorting, straightening, or batching systems first. Make sure components arrive on the line not just on time, but facing the right way up and ready to grab. Have your products oriented and lined up automatically for wrapping and sealing. Get your products grouped and counted before they get to packaging. And save your employees the physical strains of repetitive movement.

We offer complete part containment with polycarbonate top covers to prevent contamination of sensitive parts. We also have Bin Tippers to keep the Hoppers filled. Cut down on wastage and reduce downtime with our low-maintenance conveyor systems.

Types of Hopper Conveyors

- Table-top

- Modular Plastic Belts

- Hinged Steel Belts

- Magnetic Conveyors

Tailor Your Turnkey System to Your Needs

- Vision system checks the part type and orientation as well as low bin levels

- Our hopper conveyors use pneumatic grippers to lock the bins in place for safe and easy container dumping

- Increase the lifespan of your investment with wear-resistant hoppers for sharp, abrasive, or heavy components

- Customizable conveyor controls reduce downtime and improve safety

- Your new hopper conveyors can be fabricated from mild steel or stainless, depending on your environmental needs, and finished in your colors

- Clear polycarbonate hopper covers can prevent parts contamination

- Light curtains can provide for operator safety when part picking

- Stack lights can notify forklift operators when bin levels are getting low

Custom, turnkey hopper conveyor systems can revolutionize the shop floor by increasing production throughput within a safe, more organized, and efficient work environment. More comfortable employees, fewer work stoppages for component failure or missing parts, and stress-free work days are big selling points when hiring and retaining employees. Our hopper conveyor systems can help with that, too.

REQUEST A QUOTE

DOCUMENT CENTRE

- Documents not available.

Manuals & Tutorials

- Tutorials not available.

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.