CDLR CONVEYOR

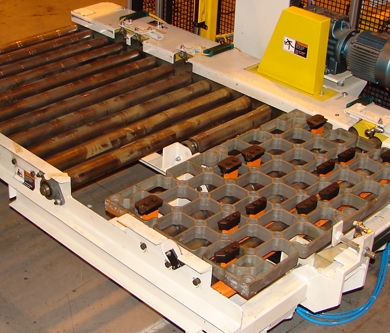

Chain Driven Live Roller (CDLR) Conveyor

Chain Driven Live Roller (CDLR) Conveyors are ideal for handling pallets, drums, rack, dunnage containers or other items that have a flat bottom. CRLR systems can be configured to be constant driven or accumulating.

Conveyor Features and Options

- Adjustable support legs

- Pneumatic Stops

- Single or multi-zone

- Pop-up Transfers

- Crowder/Locator

- Complete Control Systems

- Rollers available in 1.9″, 2.5″, 3.5″, 4.0″, and 5″ diameter.

- Slip Sleeves

- Variable Speed

- Effective widths from 3″ to 120″

REQUEST A QUOTE

DOCUMENT CENTRE

- Documents not available.

Manuals & Tutorials

Project Gallery

OUR CUSTOMERS SAY THE NICEST THINGS

"Every time we order from MC3 we already know we're going to get very high-quality products. As a buyer, I always have the confidence they're going to do things right."

Gabriela Gheorghita, Buyer, Valiant

Ready To Start Your Next Project?

Request a QuoteGet access now!

Please complete the form below to access the data sheets on this page. Click here to return home.